Fog Machine Heater Clogged

This post contains affiliate links. As an Amazon Associate, we earn from qualifying purchases.

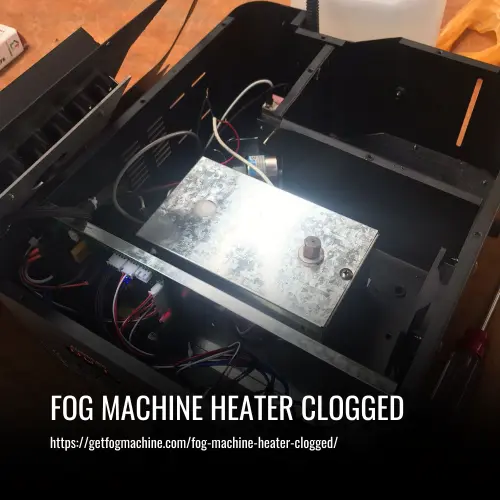

Fog machines are a major part of lighting and special effects in various events like parties, concerts, and stage performances. However, the smooth functioning of these machines can be affected due to various reasons like clogged heater blocks. A clogged heater block in the fog machine can lead to decreased fog output or even complete failure of the machine.

In this article, we will discuss the reasons behind fog machine heater block clogging, the cleaning process for the same, and the preventive measures that can be taken to avoid such situations. It is essential to read this article carefully to ensure the longevity and quality of functioning of your fog machine.

Fog Machine Heater Clogged

A fog machine works by heating up the fog fluid which then produces fog. However, in some instances, the tubes carrying the fog fluid can become clogged, decreasing the fog output. This problem is more common when using low-quality fluids or those containing additives like fragrance or color. If left unaddressed, a clogged fog machine can malfunction and even damage the heating element.

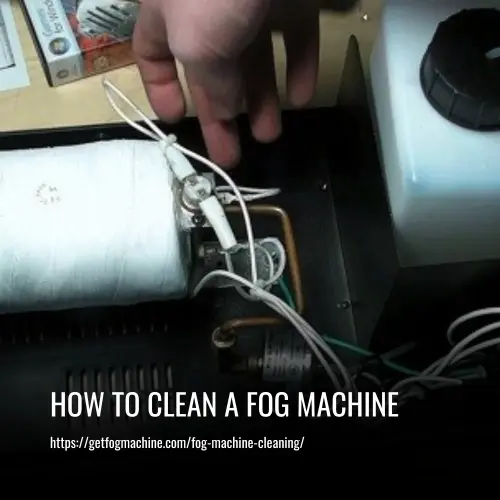

Regular cleaning is therefore essential to avoid such situations. To clean a clogged fog machine, you will need a cleaning solution made from distilled water, white vinegar, or even a vinegar-water mixture. Avoid using tap water as it contains minerals that can clog your machine further.

With the cleaning solution in hand, you can proceed to clean the heater block, output nozzle, and other parts of the device. When done right, this simple cleaning procedure can prolong the service life of your fog machine and ensure normal fog flow for your events.

Why Does a Fog Machine Heater Get Clogged

Fog machines are incredibly useful for creating unique atmospheres for parties, events, or performances. However, if you don’t take care of your fog machine properly, it can become clogged, and the output can decrease compared to normal. In this article, we’ll explore why a fog machine heater gets clogged and what you can do to fix it.

1. Thick Fluids and High Temperature

One of the most common reasons for a clogged fog machine heater is the thick nature of the fog fluid. Fog fluid has a high concentration of glycol, which gives it the thickness needed to transform into the fog we see. When vaporized at high temperatures, some of the glycol mixtures can harden, forming a residue on the heating element. This residue over time can lead to a decrease in fog output.

2. Inadequate Cleaning

Regular cleaning is essential to ensure your fog machine heater performs well and has a prolonged service life. However, some fog machine operators underestimate the importance of regular cleaning. A lack of proper cleaning procedures and the use of low-quality cleaning fluids can lead to clogged heaters and output nozzles.

How to Unclog a Clogged Fog Machine Heater

If you’re having trouble with your fog machine not generating fog, there’s a high chance that the fog machine heater is clogged. Fortunately, cleaning it is simple and easy.

Step 1: Power and Drain

The first step is to unplug the device from the power source and drain all the fog juice from the reservoir.

Step 2: Fill with Vinegar and Water

Fill the reservoir halfway with distilled water, then fill the other half with vinegar. Starting with either solution is fine since the vinegar will help break down any hardened particles inhibiting the machine’s intake system.

Step 3: Turn On

Plug your machine in and turn it on. Wait until fog starts to appear, then turn it off.

Step 4: Cleaning

Unplug the machine and empty the reservoir of the cleaning solution. Afterward, refill the reservoir halfway with the fog fluid recommended by the manufacturer.

Step 5: Test

Connect the machine to the power source and let it get warm. Turn the machine on and wait for it to produce fog.

Precautions

Never run the fog machine empty, as this will cause the pump to malfunction and potentially break. Pure vinegar should not be used to unclog the machine, as it can harm the heating element.

How Often Should Fog Machine Be Cleaned

Proper maintenance of a fog machine is crucial to ensure its longevity and optimal performance. Generally speaking, a fog machine should be cleaned every 72 hours of continuous operation to prevent clogs and damage to the heating element. Overheating due to prolonged use without cleaning can cause irreparable damage to the output nozzle, decreasing fog production and affecting the machine’s service life.

It is recommended to use distilled water or a white vinegar mixture to clean the machine, followed by a run of Fog Fluid to ensure the nozzle is clear. After cleaning, it is essential to run the machine for a few minutes to create fog before storing it. Regular cleaning prolongs the quality performance of the fog machine and minimizes the risk of costly repair services.

Benefits of Cleaning Your Fog Machine

Maintaining the performance and output of your fog machine can be achieved by regularly cleaning it. With extended use, fog juice residue can gradually clog the heater block and output nozzle, resulting in decreased fog production. Therefore, cleaning your fog machine periodically will maintain its service life.

1. Improved Performance

A clogged fog machine will produce less mist, resulting in beams of light becoming more visible and, in some cases, lying fog. Misting is important because it creates a dense enough fog that makes the beams of light visible, especially in a well-ventilated area. Regular cleaning of the fog machine ensures that the heating element warms up to produce the right amount of mist, improving the overall performance.

2. Longer Service Life

The longevity of the fog machine significantly depends on the quality of fluid used, and the frequency of cleaning. Cleaning fluids are rich in anti-corrosive properties that prevent rust and damage to the fluid containers. Regular cleaning with distilled water, white vinegar, or cleaning solutions can prolong the service life of your machine.

3. Smooth Fluid Flow

Running a fog machine without proper cleaning will cause the nozzle to develop a build-up of fog juice residue. This blockage often causes the output nozzle to deflect the mist flow and can lessen the normal fog flow. Cleaning your fog machine with a mixture of distilled water or white vinegar can effortlessly eliminate the blockage and guarantee smooth fluid flow.

How Can You Prevent A Fog Machine From Clogging

Fog machines are an essential tool for adding atmosphere and excitement to events, productions, and performances. However, even the best machines can experience clogs and malfunctions if you don’t take proper care of them. Here’s how you can prevent a fog machine from clogging and keep it running smoothly.

1. Types of Fog Fluid To Use

The type of fluid you use can significantly impact the performance and lifespan of your machine. Always opt for high-quality fog juice that is specifically designed for your fog machine. Cheaper versions with unknown or harmful ingredients can cause your machine to malfunction and clog up.

2. Regular Cleaning

Regular cleaning is vital in prolonging the life of your fog machine and preventing clogs. Clean the exterior, hose, and tank after each use, and undertake a thorough cleaning once or twice a year. However, ensure you’ve read the manufacturer’s guide to know what you can and can’t use for cleaning, as some cleaning solutions may damage your machine.

3. Proper Storage

If you won’t be using the fog machine for a prolonged period, ensure you clean it thoroughly before storing it in a cool, dry, and well-ventilated area. This will prevent clogs and ensure your machine remains in excellent condition to serve you when you need it next.

FAQs

There are several methods to clean a clogged fog machine heater. The first step is to unplug the machine and loosen any fluid containers. Then, use a firm object such as a toothbrush or cotton swab to clean the heating element. Some cleaning solutions such as white vinegar and distilled water can be effective in breaking down the residue and dissolving any blockage.

We recommend cleaning your machine after every 80-100 hours of use and prior to any long-term storage. When cleaning your fog machine, the first step is to pour all residual fluid out of the fluid tank into a catch bottle once it has cooled. This can be reused without wasting perfectly good fog fluid. It is then suggested to clean the heating element warm by running regular cleaning fluids through the fog machine until it comes out of the output nozzle free from dirt or debris. You may use solutions such as a cleaning solution, white vinegar, or a vinegar mixture with distilled water. Avoid using tap water or boiling water as it may cause serious damage.

Water can be used in fog machines, but it is not recommended. Fog machine fluids are typically water-based and are made with distilled water and glycerin to create dense and long-lasting fog. Water alone may not produce the same quality of fog or could potentially damage the machine’s internal components, such as the heating element. It is best to use quality fluid designed for fog machines to ensure normal fog flow and prevent damage to the machine.

Conclusion

Fog machines and their heaters require regular cleaning to maintain optimal performance. Neglecting to clean the heater block and output nozzle can result in decreased fog production and potentially costly repairs. The use of cleaning solutions such as white vinegar, distilled water, and specialized cleaning fluids can effectively remove buildup and prevent clogging.

It is crucial to follow the manufacturer’s cleaning procedure and utilize a well-ventilated area when cleaning the machine. Additionally, regular maintenance can extend the service life of the machine and ensure normal fog flow.