If your fog machine pump is not working, there are a few common reasons why this might be happening. Firstly, the pump may be dirty or clogged, preventing it from operating properly. In this case, you can try cleaning the pump or replacing it if necessary.

Another possibility is that the pump motor or circuit board has become damaged and needs to be replaced. Additionally, the fog fluid reservoir may be low or the type of fog fluid being used may not be compatible with the pump.

Finally, the power source or remote control may be malfunctioning, affecting the pump’s operation. By troubleshooting these potential issues, you can get your fog machine up and running again.

How Does A Fog Machine Pump Work

A fog machine pump is an essential component of a fog machine. It is responsible for propelling the fog fluid into a heat exchanger, where it is heated and converted into vapor. The pump can be powered by an electric motor or an inert gas. It draws the fog fluid from a reservoir and pushes it through a tube into the heat exchanger.

The heat exchanger then heats the fog fluid, turning it into vapor. This vapor is then expelled through a nozzle, creating the fog effect. The pump plays a crucial role in the overall functioning of the fog machine, ensuring a steady flow of fog fluid and consistent fog output.

Fixing a Dirty and Clogged Fog Machine Pump

When your fog machine pump is not working and you can hear it running but no fog is being produced, the problem is likely due to a dirty and clogged pump. Here are four simple steps to unclog and clean your fog machine pump:

Step 1: Open and Remove the Cover of the Pump

Start by unscrewing the screws along the side of the case and lifting off the lid. Inside the fog machine, you will see the tube that connects the pump to the heater. Make sure there are no visible signs of damage or blockage.

Step 2: Check the Nozzle and Unclog the Pinhole

Clogged pumps often have clogged nozzles. Carefully remove the rubber bracket that holds the fog machine together and check the nozzles. If there is a pinhole clog, use a needle to gently poke through the blockage and then soak it in hot distilled water for a few minutes. Blow through the nozzle to ensure proper airflow.

Step 3: Open the Interior of the Pump

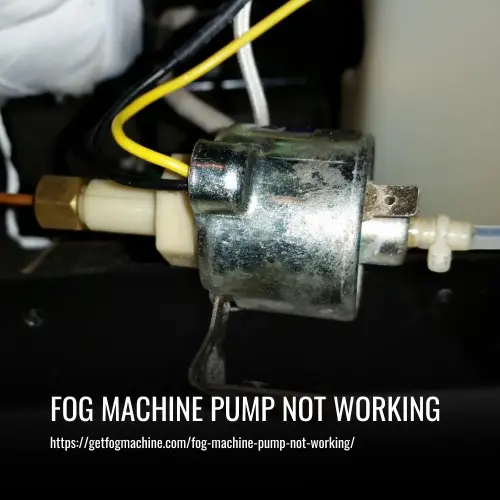

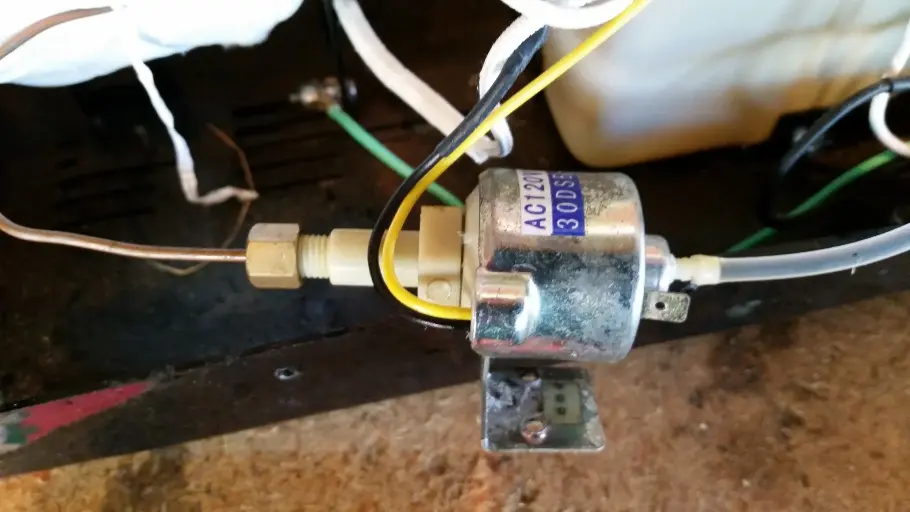

If the clog persists, remove the two screws from the cylindrical pump assembly. Inside, you will find a coil that generates a magnetic field and a piece of metal that moves up and down to pump the fog fluid. Inspect the coil for any damage. Carefully remove the keyed groove and check for loose bits or a lost glass ball, as these are vital components for the pump’s functionality.

Step 4: Disassemble and Clean the Pumping System

Once the sealed pump mechanism is exposed, disconnect the metal component and soak it in distilled water. Tap the screen to release a small ball and secure it. Remove any other components using a screwdriver, and clean all parts thoroughly before reassembling the pump.

Note: If the pump is not producing any buzzing sound at all, it may have shorted out and become overheated. In this case, the pump may need to be replaced.

By following these steps, you can effectively clean and unclog your fog machine pump, ensuring that it works properly and produces the desired fog output.

Fixing a Worn Out Pump in a Fog Machine

A fog machine pump is responsible for pumping the fog fluid from the reservoir into the heating element, creating the desired fog effect. However, over time, the pump may wear out and stop working properly. Here are eight simple steps to fix a worn-out pump in a fog pump machine.

Step 1: Dismantle the Worn Out Pump

To begin the repair process, remove the pump from the fog machine system. Drain all the fog fluid from the reservoir and disconnect the back nut on the output side of the pump. Cut the wires on the input side of the pump and remove the plugin from the reservoir.

Step 2: Find Materials for Repairing the Pump

Before starting the repair, gather the necessary materials from your local hardware or auto parts store. Consider using a windshield washer pump or any other motor that operates on 12 volts of direct current as a replacement.

Step 3: Correct the Output Voltage Using a Transformer

Since the fog machine pump operates on 120 volts alternating current, you need to correct the voltage output. Use a transformer to convert the 120-volt alternating current from your home to 12 volts direct current. Consider replacing the printed circuit board if needed.

Step 4: Modify the Pump

Connect the modified pump to the fog machine system by using tubing and barbed fittings. Drill a quarter-inch hole around the washer pump’s perimeter and attach the adapter using a rubber mallet. Connect the adapter to the heating element input using compression fittings.

Step 5: Design an Adapter

To complete the tube connection process, leave a knot in the tubing and secure the compression fittings. Use a crescent wrench to tighten the fittings onto the ferrule. Connect the new pump to the reservoir and ensure a secure fit.

Step 6: Connect the Transformer to the Modified Pump

Connect the input and output tubes of the modified pump to the heating element. Install a transformer to convert the voltage output from 120 volts alternating current to 12 volts alternating current. Wire nut or cut off the black lead and connect the two yellows to achieve the desired voltage.

Step 7: Mount the Pump on the Fog Machine

Find empty spots within the fog machine to mount the electrical connections, similar to where the original pump motor was connected. Use butt splices to connect the transformer to the circuit board and diode. Install the transformer at the bottom of the wall.

Step 8: Test the Pump and Troubleshoot

Use a voltage meter to confirm that the pump is receiving the correct voltage. Perform preliminary troubleshooting to ensure all connections are secure and that the pump is functioning correctly. Place the reservoir tank in its proper location and allow the pump to run, generating fog.

If these steps do not fix the issue, there may be other causes such as a clogged heater or a leak in the fog machine system. Consult the manufacturer’s instructions or consider seeking professional assistance if further troubleshooting is needed.

How Do You Clean A Fog Machine Pump

Cleaning a fog machine pump is essential to ensure optimal performance and longevity of the equipment. Here is a step-by-step guide on how to clean a fog machine pump:

1. Prepare the cleaning solution

Mix equal parts of water and white vinegar to create a solution suitable for cleaning the pump. This solution acts as a solvent to dissolve impurities that may be clogging the pump.

2. Fill the fog fluid reservoir

Empty the existing fog fluid from the reservoir and replace it with the cleaning solution prepared in step one. Ensure the pump is not connected to the power source during this process.

3. Power up the fog machine

In a well-ventilated area, power up the fog machine and let it heat up as usual. The heat will cause the cleaning solution to circulate through the pump, helping to break down any debris or build-up.

4. Activate the fog machine

Activate the fog machine by using the remote control or the designated button. Allow the cleaning solution to flow through the pump and out of the fog machine. This process helps to flush out any impurities that may be trapped in the pump.

5. Repeat if necessary

If the fog machine pump is severely clogged or dirty, you may need to repeat steps two to four using a fresh batch of cleaning solution. This will ensure thorough cleaning of the pump components.

6. Refill with fog fluid

Once the cleaning process is complete, empty the cleaning solution from the fog fluid reservoir and refill it with the appropriate type of fog fluid. Make sure to use a reputable brand and follow the manufacturer’s guidelines for the proper type of fog fluid to use.

By following these steps, you can effectively clean a fog machine pump and maintain its performance for longer-lasting use. Regular cleaning and maintenance of the fog machine pump will help prevent clogs and ensure optimal fog output during performances or events.

FAQs

The most commonly used pump in professional fog machines for the entertainment industry is a piston pump. It offers efficiency, and a long performance life, and provides high-volume fog output.

The average flow rate of a fog machine pump ranges from 60 to 210 ml/min. This rate determines the speed at which the fog fluid is pumped into the heating element.

Yes, fog machines are prone to clogging. This is primarily due to the thick consistency of the fog fluid and the high temperature at which it vaporizes. If your fog machine exhibits decreased output or the pump is not working, cleaning the pump may help resolve the issue.

Conclusion

In conclusion, a fog machine pump not working can be a frustrating issue, but there are several potential causes and solutions to consider. First, check the power source and ensure it is properly connected and supplying sufficient power to the pump motor. Next, inspect the pump assembly for any signs of damage or clogs that may be impairing its function. If needed, replace the pump motor or any other faulty components such as the circuit board or heating element.

Additionally, make sure to use the correct type of fog fluid and not mix different types or dilute it with water, as this can affect the pump’s performance. Regular maintenance, such as cleaning the pump tube and reservoir with white vinegar, can help prevent clogs and ensure smooth operation. If all else fails, consult the manufacturer or consider investing in a replacement pump altogether.